Chigayo chekucheka chepamusoro chinogona kupedzisa katatu kuwanda kwezvishandiso zvakajairika munguva imwe chete uku ichideredza kushandiswa kwesimba ne20%. Uku hakusi kukunda kwetekinoroji chete, asiwo mutemo wekupona wekugadzirwa kwemazuva ano.

Mumachina mashopu, ruzha rwakasiyana rwevanotenderera vanocheka vanocheka vachisangana nesimbi runoumba rwiyo rwekutanga rwekugadzira kwemazuva ano.

Ichi chishandiso chinotenderera chine akawanda ekucheka macheto chinoumba zvese kubva kudiki nhare mbozha kusvika kune hofori zvimiro zvendege nekunyatsobvisa zvinhu kubva pane workpiece pamusoro.

Sezvo indasitiri yekugadzira ichiramba ichikwidziridza yakanangana nepamusoro uye nehunyanzvi hwepamusoro, tekinoroji yekucheka milling iri kuita shanduko yakanyarara - iyo bionic structure milling cutter inogadzirwa ne 3D kudhinda tekinoroji yakareruka ne60%, asi hupenyu hwayo hwakapetwa kaviri; iyo yekuputira inowedzera hupenyu hwechishandiso ne200% painogadzirisa alloys akakwira-tembiricha.

I. Milling cutter basics: tsananguro uye yakakosha kukosha

A milling cutter chishandiso chinotenderera chine zino rimwechete kana anopfuura, rimwe nerimwe rawo sequentially uye nekupindira rinobvisa workpiece stock. Sechishandiso chepakati mukugaya, inoita mabasa akakosha senge machining ndege, nhanho, grooves, kuumba nzvimbo, uye kucheka maworkpiece.

Kusiyana nekucheka-poindi imwe chete mukutendeuka, vanocheka milling vanovandudza machining nekucheka pamapoinzi akawanda panguva imwe chete. Kuita kwayo kunobata zvakananga kurongeka kweworkpiece, kupera kwepamusoro, uye kugona kwekugadzira. Mumunda wemuchadenga, chigayo chepamusoro-chekuita chinogona kuchengetedza kusvika ku25% yenguva yekugadzira kana uchigadzira zvikamu zvechimiro chendege.

Mukugadzira mota, kunyatsoita fomu milling cutters inotarisisa kurongeka kwakakodzera kwezvinhu zvakakosha zveinjini.

Iko kukosha kweiyo milling cutters iri mumubatanidzwa wavo wakakwana wekuita zvakasiyana uye kushanda nesimba. Kubva kukurumidza kubviswa kwezvinhu mukuita roughing kusvika pakurapwa kwepamusoro mumachina akanaka, mabasa aya anogona kupedzwa pamuchina mumwe chete wemuchina nekungochinja akasiyana kucheka zvigayo, zvichideredza zvakanyanya mari yekushandisa uye kugadzirwa kwekuchinja nguva.

II. Nhoroondo yemamiriro: tekinoroji shanduko yevanocheka vanocheka

Nhoroondo yekusimudzira yevanocheka milling inoratidza shanduko yetekinoroji muindasitiri yese yekugadzira michina:

1783: Injiniya wekuFrance René akagadzira nyika yekutanga yekuchekesa, achivhura nguva nyowani yekucheka-shanduka kwemazino akawanda.

1868: Tungsten alloy tool simbi yakatanga, uye kumhanya kwekucheka kwakapfuura mamita masere paminiti kekutanga.

1889: Ingersoll akagadzira revolutionary corn milling cutter (spiral milling cutter), achiisa blade mukati memuouki cutter body, iyo yakava prototype yemazuva ano yekucheka chibage.

1923: Germany yakagadzira simende carbide, iyo yakawedzera kumhanya kwekucheka nekanopfuura kaviri iyo yesimbi inomhanya kwazvo.

1969: Patent yemakemikari vapor deposition coating tekinoroji yakapihwa, ichiwedzera hupenyu hwechishandiso ne1-3 nguva.

2025: Metal 3D-yakadhindwa bionic milling cutters vanowana kudzikiswa kwehuremu ne60% uye nekaviri hupenyu hwavo, vachityora miganhu yemaitiro echinyakare.

Yese innovation muzvishandiso uye zvimiro zvinofambisa kukura kwejometri mukubudirira kwekugaya.

III. Kuongororwa kwakadzama kwekugadzika kwekucheka kwegayo uye mamiriro ekushandisa

Zvinoenderana nekusiyana kwechimiro uye basa, milling cutters inogona kukamurwa kuva anotevera marudzi:

| Type | Mamiriro ezvinhu | Applicable Scenarios | Indasitiri yekushandisa |

| Zvigayo zvinopera | Kucheka mipendero pane zvese denderedzwa uye yekupedzisira zviso | Groove uye nhanho yepamusoro yekugadzirisa | Kugadzira mold, general muchina |

| Face milling cutter | Huru dhayamita multi-blade kupera chiso | Kugaya hombe kwepamusoro-soro | Mota cylinder block uye zvikamu zvebhokisi |

| Side and face milling cutter | Kune mazino kumativi ose uye denderedzwa | Precision groove uye nhanho kugadzirisa | Hydraulic valve block, gwara renjanji |

| Bhora kupera zvigayo | Hemispherical cutting end | 3D pamusoro pekugadzirisa | Aviation blades, mold cavities |

| Mucheka wekugaya chibage | Spiral kurongeka kwekuisa, hombe chip nzvimbo | Heavy kugaya pfudzi, deep grooving | Aerospace structural parts |

| Saw blade milling cutter | Zvimedu zvitete zvine mazino akawanda uye yechipiri deflection angles kumativi ese | Kuchera kwakadzika nekuparadzana | Zvimedu zvitete zvine mazino akawanda uye yechipiri deflection angles kumativi ese |

Chimiro chechimiro chinotarisa hupfumi uye kushanda

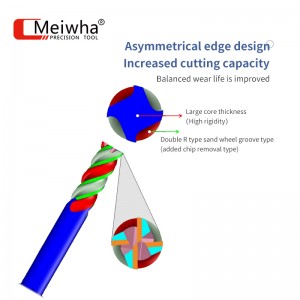

Integralmilling cutter: Muviri wekucheka uye mazino akaumbwa akabatanidzwa, ane kusimba kwakanaka, akakodzera diki dhayamita chaiyo machining.

Indexable milling cutters: inodhura-inoshanda kutsiva yekuisa kwete chishandiso chose, chakakodzera roughing.

Welded milling cutter: carbide tip yakasungirirwa kune simbi muviri, inodhura asi ine shoma yekugaya nguva

3D yakadhindwa bionic chimiro: yemukati muzinga retisi dhizaini, 60% kuderedza uremu, yakagadziridzwa vibration kuramba.

IV. Scientific Selection Guide: Key Parameters Matching Processing Zvinodiwa

Kusarudza mucheki weguyo kwakafanana nachiremba anonyora tsamba yekunyora - iwe unofanirwa kunyora mushonga wakakodzera wemamiriro chaiwo. Aya anotevera ndiwo akakosha tekinoroji zvinhu zvekusarudza:

1. Diameter kuenderana

Kucheka kudzika ≤ 1/2 chishandiso dhayamita kudzivirira kupisa uye deformation. Paunenge uchigadzira dzakatetepa-yakavezwa aluminium alloy zvikamu, zvinokurudzirwa kushandisa diki dhayamita yekupedzisira chigayo kuderedza kutema simba.

2. Kureba kweblade uye nhamba yemashizha

Kucheka kudzika ≤ 2/3 yehurefu hweblade; kuitira roughing, sarudza 4 kana mashoma mablades kuti uone chip nzvimbo, uye pakupedzisa, sarudza 6-8 blades kuti uvandudze kunaka kwepamusoro.

3. Kushanduka kwezvinhu zvekushandisa

High-speed simbi: high toughness, yakakodzera kukanganiswa kucheka

Cemented carbide: sarudzo huru, kuomarara kwakadzikama uye kuoma

Ceramics/PCBN: Precision machining ezvemhando yepamusoro, sarudzo yekutanga yesimbi yakaoma

HIPMS kupfekedza: New PVD coating inoderedza yakavakirwa-kumusoro uye inowedzera hupenyu ne200%

4. Geometric parameter optimization

Helix angle: Paunenge uchigadzira simbi isina tsvina, sarudza diki helix angle (15 °) kuti uwedzere kumucheto simba.

Tip Angle: Pazvinhu zvakaoma, sarudza kona hombe (> 90°) kuwedzera rutsigiro

Vagadziri vemazuva ano vachiri kupikiswa nemubvunzo usingaperi: maitiro ekugadzira simbi yekucheka yakatsetseka semvura inoyerera. Mhinduro iri mupfanha dzouchenjeri dzinobonderana pakati pebadza rinomonereka noungwaru.

[Bata nesu kuti tipe mishonga yekucheka nekugaya]

Nguva yekutumira: Aug-17-2025