Iyo ine simba isingaperi magineti chuck, sechinhu chinoshanda, chekuchengetedza simba uye chiri nyore-kushanda-chishandiso chekubata mabasa, chinoshandiswa zvakanyanya munzvimbo dzakasiyana senge simbi kugadzirisa, kusangana, uye welding. Nekushandisa magineti echigarire kupa simba rinoramba richikwevera, iro rine simba remagineti rekukweva kapu rinowedzera zvakanyanya kushanda zvakanaka kwekugadzira, kuchengetedza nguva uye mutengo. Ichi chinyorwa chinopa sumo yakadzama kune iyo tekinoroji misimboti, zvigadzirwa zvakanakira, zvirambidzo zvekushandisa uye nzira dzekugadzirisa dzeiyo ine simba isingaperi magineti yekuyamwa kapu, ichibatsira vashandisi kunzwisisa zviri nani uye kushandisa iyi michina.

I. Technical Principle yeSimba Permanent Magnetic Chuck

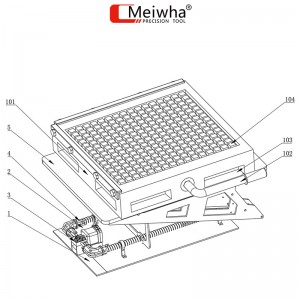

Chuck Yemukati chimiro dhayagiramu

1.Three-dimensional magnetic circuit superposition design

- Double-layer magnetic pole chimiro:

A kaviri-layer magnetic circuit inoumbwa nekushandisa inverted T-shaped core uye side-lying plate. Neodymium-iron-boron magineti simbi (ine N pole yakatarisana) uye yepasi aruminiyamu-nickel-cobalt magineti simbi inoumba matatu akazvimirira akavharwa maseketi. Mitsetse yesimba remagineti inotenderera kubva pakati → chidimbu chekushanda → ndiro yekunze → ndiro yepasi → musimboti, nokudaro ichiwedzera simba remagineti neinodarika 16%.

- Magnetic centripetal inotarisa:

Iyo inverted T-yakaita musimboti inoshandura mitsara yemagineti kumapendero akananga pakati, achigadzirisa nyaya yekusakwana kwekunamatira kune nhete yebasa (senge madhairekitori uye blades), uye hushoma hunoenderana saizi yebasa inosvika 50 × 50 × 2mm.

2.Halbach Array Enhancement

- Muchinjikwa-chakaumbwa chisingaperi magineti array:

Iyo yepamusoro-yekupedzisira modhi inotora maviri-dimensional "muchinjikwa" mhando Halbach array. Kuburikidza negadziriro chaiyo yemagineti echigarire (ane mapango eNS anotenderera achitenderedza), inotungamira inotungamira kwainoenda kune magineti, ichiwedzera iyo magineti flux density kune rimwe divi renzvimbo yekushanda ne50% uye ichidzikisa kuvuza kwemagineti ne30%.

- Optimization yeMagnetic Energy Utilization Rate:

Pasi pevhoriyamu imwe chete, iyo Halbach array inowedzera simba remagineti density kubva pa120N/cm² mune yechinyakare dhizaini kuenda ku180N/cm², uku ichidzikisa kushandiswa kwezvinhu ne20%.

| Rudzi rwemagineti zvinhu | basa rinokosha | performance parameter | application Scenarios |

| NdFeB (neodymium iron boron) | High coercivity (≥ 955 kA/m) anti-demagnetization kugona | Remanent magnetism Br = 1.26 - 1.29 T | Iyo huru yemagineti pole inovimbisa kunamatira kwakasimba. |

| Aluminium-nickel-cobalt | Yakakwira yakasara magineti (Br = 1.3T) inosimudzira simba remagineti | Kushanda tembiricha ≤ 460 ℃ | Inobatsira magineti pole, inowedzera kugadzikana kwekupisa |

| LNG inogara magineti | Variable polarity, inoteerera kune magetsi ekudzora zviratidzo | Simba rekuchengetedza: 56 kA / m | Magnetic redunhu switching execution layer |

Synergistic mhedzisiro: NdFeB inopa anti-demagnetization kugona, AlNiCo inosimudzira iyo magineti yekupinda simba, LNG inogonesa polarity kudzoreredza. Zvinhu zvitatu izvi zvinobvisa mutsauko wemagineti kuburikidza nebhafa magineti joko, kuve nechokwadi chekuti magineti asara anosvika zero panguva ye demagnetization.

II. Product Advantages of High-Intensity Permanent Magnetic Chuck

Meiwha CNC Chuck

1.No kudiwa kwekunze kwesimba sosi

Iyo ine simba isingaperi magineti Chuck inopa simba rekugadzirisa kuburikidza neanogara magineti uye haidi magetsi. Kune dzimwe nzvimbo dzekushanda dziri kure nemasimba emagetsi kana kuti zvisingakwanisi kushandisa magetsi, iyo inogara magnetic chuck inopa mhinduro iri nyore.

2.Quick Installation uye Disassembly

Kuenzaniswa neyechinyakare mechanicha zvigadziriso kana electromagnetic suction makapu, ine simba isingaperi magineti chuck ine kukurumidza kuisirwa uye disassembly kumhanya. Nekungoshanda kuri nyore, iyo workpiece inogona kugadziriswa kana kuburitswa, nekudaro ichiwedzera kugadzirwa kwemutsara kunyatsoshanda. Iwo akanyanya kukodzera kugadzirisa nharaunda uko maworkpieces anoda kuchinjwa kazhinji.

3.Kusveta kwakadzikama kunovimbisa kugadzirisa kurongeka

Iyo ine simba isingaperi magineti chuck inopa yunifomu uye yakagadzikana adhesion simba, zvinobudirira kudzivirira iyo workpiece kubva pakufamba kana kudedera panguva yekugadziriswa, nekudaro kuvandudza iko kurongeka uye kugona. Inonyanya kukodzera kugadziriswa kwakarurama.

4.Save nzvimbo mari

Nekuda kwekushaikwa kwesimba rekupa uye yakaoma kudzora masisitimu, ane simba anogara magineti chucks anowanzo kugadzirwa kuti awedzere compact, achivaita akakodzera nzvimbo dzekushanda dzine nzvimbo shoma. Uyezve, mutengo wavo wakaderera wekugadzirisa uye hupenyu hwesevhisi hurefu hunogona kunyatso kudzikisa mutengo wekugadzira.

5.Yakakwirira inogadziriswa, yakakodzera kune dzakasiyana-siyana workpieces

Iyo ine simba isingaperi magineti chuck haingogone kubata echinyakare simbi workpieces, asi zvakare kuchinjika kune akasiyana maumbirwo uye saizi yebasa rekushanda. Inogona kugadzirisa zvisina kujairika uye zvakasiyana gobvu simbi zvinhu, kusangana zvakasiyana kugadzirisa zvinodiwa. (Parutivi, customizable magineti pole marongero akarongwa kutsigirwa)

III. Inorambidzwa Zvikumbiro zveHigh-Intensity Permanent Magnetic Chuck

Kunyangwe zvine simba zvechigarire magineti chuck ine yakakura maapplication mukugadzirwa kwemaindasitiri, vashandisi vachiri kufanira kuziva zvinotevera zvinorambidzwa kana vachizvishandisa, kuitira kudzivirira kukuvara kwemidziyo kana kusashanda zvakanaka.

1.Dzivisa kutarisana kwenguva refu kune kupisa kwakanyanya.

Kupisa kwakanyanya kunokonzeresa kuti magineti emagetsi echigarire aite kupera simba zvishoma nezvishoma. Kunyanya kune yakakwirira-isingawanzo epasi magineti, kuratidzwa kwenguva refu kune nharaunda inopfuura yavo yekushanda tembiricha yemhando inogona kutungamira mukudzikira kwesimba rekudhonza. Naizvozvo, yakasimba inogara magineti chuck inofanirwa kudzivirira kushandiswa munzvimbo dzekushanda dzine tembiricha yakanyanya.

2.Dzivisa kusangana nemagineti akasimba

Iyo yakasimba inogara magineti chuck yatove ine simba remagineti yakasimba pachayo. Kana ikasangana neakasimba magineti sosi, inogona kukonzera simba remagineti kudzikira kana kukuvadza kapu yekuyamwa. Izvo zvinodikanwa kuve nechokwadi chekuti yakasimba inogara magineti chuck inochengetwa kure nemagetsi emagetsi, yakakwira-frequency michina, nezvimwe.

3.Dzivisa kusangana zvakananga nezvinhu zvinoparadza

Zvinhu zvinosvibisa kemikari zvakaita seasidhi yakasimba uye mabhesi akasimba zvinogona kukanganisa pamusoro pechigarire magineti chuck, zvichiita kuti midziyo yayo yemagineti iderere kana kukuvara. Panguva yekushanda, zvinodikanwa kuti udzivise kapu yekuyamwa ichipinda mukubata kwenguva refu nezvinhu izvi, kunyanya izvo zvisina matanho ekudzivirira.

4.Avoid Overload Application

Kunyangwe iyo ine simba isingaperi magineti chuck ichipa hombe yekukweva simba, ine zvakare ine muganho wekutakura. Kuwedzeredza kunogona kutungamira kune magineti attenuation uye kunyangwe kukuvadzwa kune chuck chimiro, zvichiunza njodzi yekuchengetedza. Nokudaro, kana uchiishandisa, uremu hwakakodzera hwe workpiece hunofanira kusarudzwa zvichienderana nezvinodiwa zve chuck.

IV. Maintenance Nzira Dzakasimba Chisingaperi Magnetic Chuck

Kugadzirisa kwakakodzera hakungowedzere hupenyu hwebasa reiyosimba risingaperi magnetic chuck, asi zvakare chengetedza maitiro ayo ekunamatira. Hedzino dzimwe nzira dzakajairika dzekugadzirisa:

1.Kuchenesa nguva dzose

Kumusoro kwechuck kunofanira kucheneswa nguva dzose kudzivirira kuunganidzwa kwesimbi shavings, mafuta mavara kana mamwe marara. Izvi zvinonyanya kukosha panguva yekugadzirwa kwesimbi. Iwe unogona kuchenesa pamusoro uchishandisa mweya wakamanikidzwa kana jira rakapfava. Hazvikurudzirwe kushandisa zvinhu zvakaoma kuikwenya, sezvo izvi zvinogona kukuvadza magineti.

2.Regularly tarisa magineti

Kunyangwe zvisingaperi magineti chucks asingavimbe nekunze kwesimba sosi, simba ravo remagineti richaramba richipera zvishoma nezvishoma sezvo nguva yekushandiswa inowedzera. Izvo zvinodikanwa kugara uchitarisa simba rekusveta remakapu ekusveta kuti uone kuti inoramba iri padanho rakajairwa. Kana simba rekukweva rakadzikiswa zvakanyanya, kufunga kunofanirwa kupihwa kutsiva magineti kana kuita kugadzirisa.

3.Dzivisa kudhumhana

Magineti ari musimba remagineti chuck ane simba asina kusimba. Kukanganisa kwakanyanya kunogona kuita kuti magineti atyoke kana simba remagineti kukundikana. Panguva yekushanda, munhu anofanira kungwarira kuti arege kudhumhana kusingakoshi.

Thesimba risingaperi magnetic chuck, ine mabhenefiti ayo akadai sekushaikwa kwemagetsi, kukurumidza kuisirwa uye disassembly, uye yakagadzikana yekuyamwa simba, chave chishandiso chakakosha mukugadzirwa kwemazuva ano kwemaindasitiri. Nekushandisa kwakaringana uye kugadzirisa, inogona kuwedzera zvakanyanya kugadzirwa kwekugadzira uye kugadzirisa iko kurongeka. Kunzwisisa misimboti yayo yehunyanzvi, zvakanakira, pamwe nekushandisa kwayo uye nzira dzekugadzirisa ndiyo kiyi yekuve nechokwadi chekushanda kwayo kwenguva refu.

referensi zvinhu:

Magnetic Clamping Technology-Nhungamiro pane maindasitiri magineti clamps uye mashandisiro awo.

Industrial Magnetism-Nheyo dzemagineti echigarire anoshandiswa mumaindasitiri maturusi.

Ongorora: Iwo chaiwo maparamendi echigadzirwa ari pasi peruzivo rwazvino rwunopihwa nemugadziri. Ndokumbira ushanyire nzvimbo yedu yechigadzirwa kuti udzidze zvakawanda nezve mamodheru kana kukumbira rondedzero yesarudzo!

Nguva yekutumira: Aug-14-2025